Download Print Friendly Version: Dutch Hungarian Italian Russian Polish Chinese German Czech Swedish French Spanish English

How to Guide - Exposing PLUS emulsions and choosing the right exposure system

Synopsis...

Once the PLUS emulsion has been coated on the mesh and dried, it is ready for exposure. The objective with exposure is to penetrate the photostencil material all the way through to the mesh to ensure hardening around the filaments and thus obtain good stencil adhesion whilst accurately reproducing the detail on the film positive.

Underexposure

If the exposure is not enough and the whole layer is not penetrated by the UV light, the stencil may wash completely off on washout. Or, more typically the stencil may be intact after washout, but break down or become tacky during the print run - both of which are symptomatic of under exposure.

Overexposure

As a general rule, "direct" systems do not suffer from a lack of flexibility on over-exposure, in fact, if anything, the adhesion to the mesh is improved. However, the resolution and definition of the image deteriorate as the stencil is over exposed. See sections on light geometry and mesh influences for further information.

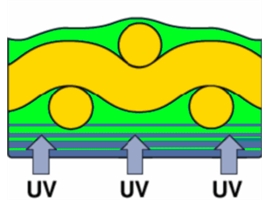

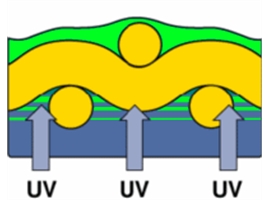

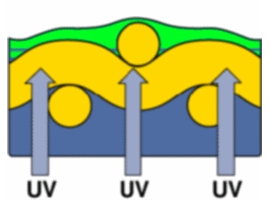

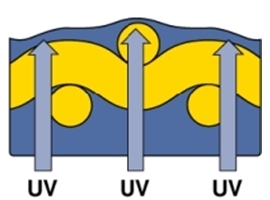

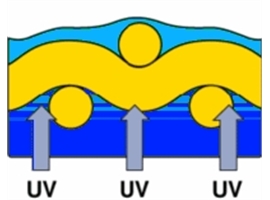

The following diagrams outline the effects of under-exposure at 1/4, 1/2 and 3/4 of the optimum exposure for a Diazo sensitised PLUS emulsion.

You can clearly see from the diagrams above, how the yellow Diazo sensitiser loses its yellow colouration as it reacts to the Ultra Violet light and consequently the green emulsion changes back to the original blue colour seen before it was sensitised. As the Diazo reacts, the UV light penetrates further and further into the stencil, progressively hardening the emulsion as it goes.

Optimum exposure

At full exposure all the emulsions is fully hardened and the stencil will provide the optimum resistance and durability.

Top tip: It is always advisable to inspect the stencil using white light when you are trying to determine the correct exposure as the yellow colour change will show up much better under white light than under yellow safelight.

AUTOTYPE EXPOSURE CALCULATOR

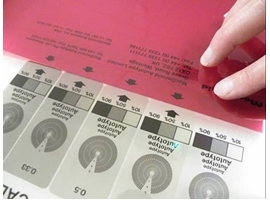

What is the Autotype Exposure Calculator? The exposure calculator is a film positive comprising of five columns, each with a resolution target, a set of halftone tints and lines of text. Four of the columns are backed with a grey neutral filter of different density. This concept enables five different exposures to be made simultaneously.

Why use the Autotype Exposure Calculator? Incorrect exposure is one of the most frequent causes of stencil failure. The Exposure Calculator provides a quick, accurate determination of exposure times with all photostencil systems to alleviate this problem. It can also be used as a printing aid to optimise print quality, or as a means of process control.

How to use the Autotype Exposure Calculator?

1. Estimate the correct exposure time using the guidelines available. Then DOUBLE it.

2. Expose the photostencil to the Exposure Calculator in the normal way, washout and dry thoroughly.

3. Examine the stencil to determine the correct exposure time. Interpretation of correct exposure depends on the stencil system.

Reading the results of the exposure test - Capillex and Diazo sensitised PLUS emulsions:

The stencil will show variations in colour from one factor to the next. Follow the colour change from the lightest to the darkest until it stops. The factor where the colour change stops is the column that represents optimum exposure. Once the correct factor has been chosen, multiply the factor by the test exposure time. This gives the correct exposure time (or number of units) for that particular stencil/mesh/light source combination.

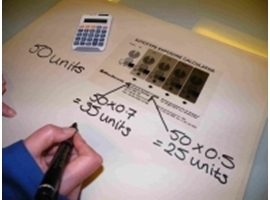

Example: 0.7 x 50 units = 35 units

Correct factor x test exposure = Correct Exposure

If there is still a colour change between Factor 0.7 and Factor 1, this indicates an under-exposed stencil, DOUBLE the original test exposure, and repeat the test.

Post exposure of a Diazo stencil

Post exposing a Diazo sensitised stencil will have little to no effect on improving its resistance.

Reading the results of the exposure test - Photopolymer emulsions (PLUS 1-SR, 9000, AQUA, MIDI):

Under-exposed Photopolymer stencils are also weak and will quickly break down, so it is important to try and maximise the exposure time without compromising the detail you need to print. It is actually quite a bit harder to determine the optimum exposure with a Photopolymer stencil than with a Diazo as there is no obvious colour change to help guide you.

Typically the optimum exposure is determined by looking at a combination of resolution and through-cure. Use the Autotype Exposure Calculator for your test exposure and then whilst the stencil is still wet after washout, look for through-cure on the squeegee side. You can either use your finger to gauge softness, or try putting a sheet of unprinted newspaper on the squeegee side and seeing if it sticks to the soft emulsion. The optimum exposure (with respect to print durability) is where all the emulsion has been hardened by the UV light and is not soft on the squeegee side.

You then need to dry the test screen and check the resolution to make sure it will print the detail that you need. You can refer to the working instructions for the Autotype Exposure Calculator to identify what line width the stencil is resolving at each exposure factor and then check this against your film positive.

Simple test for through-cure, Step 1

Expose the stencil using the Exposure Calculator. It is good practice to blank off the bottom of the calculator using either Automask Ruby or a sheet of black paper. This will create an open area of mesh immediately below the targets for the rub test. NOTE a photopolymer stencil will typically be much faster than a Diazo stencil often needing only 1/10 of the exposure time.

Simple test for through-cure, Step 2

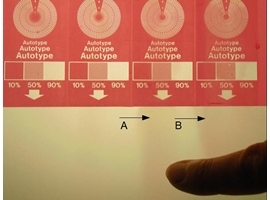

While it is still wet, rub the squeegee side of the stencil over the different factors. If the emulsion feels soft and is easily removed then it is under exposed.NB it is possible to wash away this soft emulsion using a long/strong wash out from the squeegee side so do not over-develop the test screen.You can see from the image below how the soft emulsion from the 0.25 factor has been drawn out into the open mesh (B) to give a noticeable stain. The degree of softness is less at the 0.33 factor (A) and less emulsion is drawn out. At the 0.5 factor on this stencil the emulsion on the squeegee side has been hardened and the stencil is fully exposed.

Another method that can be used for photopolymer emulsions on a medium/fine mesh counts is to see if a sheet of newsprint will stick to the soft emulsion after washout. Simply lay a sheet of newspaper (preferably unprinted) on the squeegee side of the wet screen and then use a roller to push it into contact. If you can feel the newspaper sticking to the stencil it is a sign that the screen is underexposed.

Caution - the results can be influenced by mesh count, stencil thickness and how well the stencil has been washed out, so a negative result does not always mean full exposure, however a positive result will indicate underexposure.

Simple test for through-cure, Step 3

Dry the screen and examine the targets. Determine which factor resolves the finest line you need to print? NOTE it will be impossible to resolve the fine detail at the centre of the target using a white mesh and exposed to a bank of Fluorescent tubes!

Using a combination of stencil hardness (through cure) combined with resolution, it is possible to determine which factor will give the best result for your application. Multiply your test exposure time by this factor to establish the optimum exposure time.

Exposure determination using a 21 step wedge.

It is possible to use a 21 step (0.15 density) step wedge to determine correct exposure but there is a word of caution. The optimum exposure is a solid step 8, however the test can be influenced significantly by the type of washout used. It is possible to wash back the step wedge by as much as two steps if a long/strong washout is used and a 2 step difference is a 100% difference in time. The 21 step wedge can be a useful tool however in determining any drift in the exposure time as long as the washout conditions remain constant.

Post exposure of Photopolymer stencils

Unlike Diazo stencils a post exposure after processing can increase the solvent resistance of a photopolymer stencil. This can be achieved by either re-positioning the processed and dried screens back in front of the UV exposure unit or simply by leaving the screens in a white light area for several hours. Please note however if the stencil has been grossly underexposed and the soft emulsion washed away from the squeegee side then no amount of post exposure can harden emulsion that is not there! It is always better to achieve optimum exposure in the first place rather than rely on the hardening effect from a post exposure.

The Exposure Calculator as a printing guide

The Exposure Calculator can be used to assess printed edge definition (straightness/clarity of the printed edge) and print resolution (fineness of detail achievable).

The target is designed to allow the user to select the best angle to position the film positive stencils in order to avoid " saw tooth" and mesh interference. Resolution is checked by assessing the degree of "filling in " at the centre of the target.

Tints

The 10% and 90% areas can be used to gauge the degree of highlight dot loss and flooding of shadow areas respectively.

The use of a square dot configuration means that the corners of the dots just meet at 50%. Examination of a print will show at a glance whether there is dot loss or dot gain in the mid-tone.

Failure of the corners to meet indicates dot loss. This may be due to undercutting caused by over-exposure, poor light geometry, drying in of ink, or the choice of a low resolution photostencil.

The merging of dots, or thickening of the join between dots, indicates dot gain. This is due to flooding which may be caused by over-thinning of ink, or by the use of a photostencil with poor edge definition. Before starting a print run with, it is always recommended that a test strip is printed, which contains a full range of tone values in the selected dot count.

NB: Positives with square dots are not recommended for fine halftone printing.

Change in exposure time for new lamp distance

Once the exposure has been fixed for a specific film it should be maintained. If the distance between the light source and the film changes, the exposure must be changed accordingly, unless of course, an integrator is used and the exposure time is changed automatically.

Download Print Friendly Version Dutch Hungarian Italian Russian Polish Chinese German Czech Swedish French Spanish English